I dodged a bullet last year when our Sugar Maple dropped a sizable limb on mom and dad’s rig out back. The limb landed squarely on the air conditioner which somehow managed to survive the collision and still operates but the cover was understandably destroyed. As luck would have it, the roof is structurally reinforced in that area so had it happened anywhere else it’s likely that the damage would have been considerably more extensive. The roof membrane only had a few small abrasions and tears which were easily repairable.

The principal damage appeared to be internal to the roof which I assumed was one or more broken trusses. From the inside, the roof drooped a little where normally it would be flat, however it was hardly noticeable and the rig has been used a couple times since the incident without issue. Over the last winter, we had a decent amount of snow that accumulated and stayed on it for the better part of January and I surmise that this added load pushed the roof down a little further. I observed that it was more noticeable than last year so with mom and dad returning this week for what is likely an extended stay, I knew I better resolve the issue before they arrived.

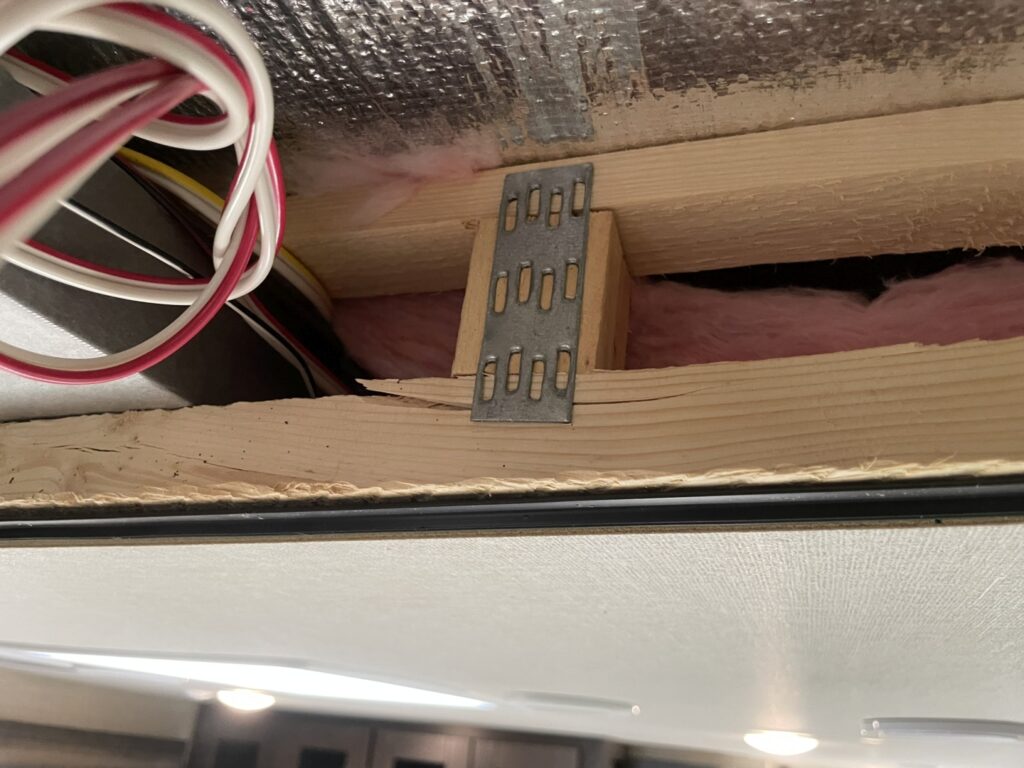

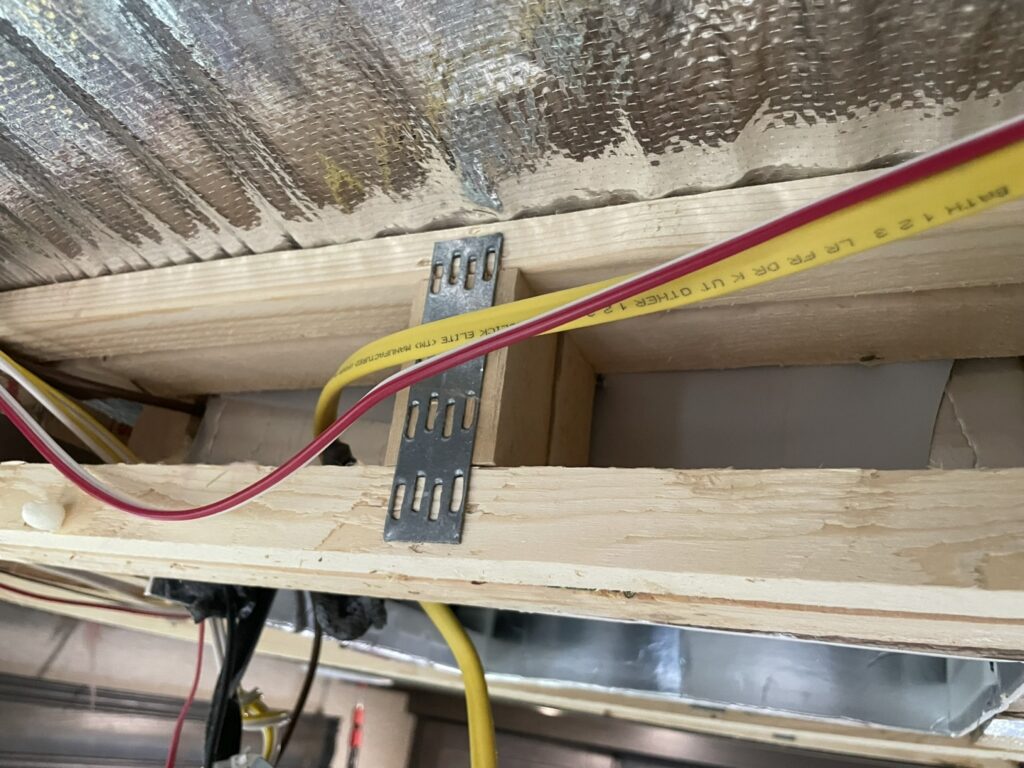

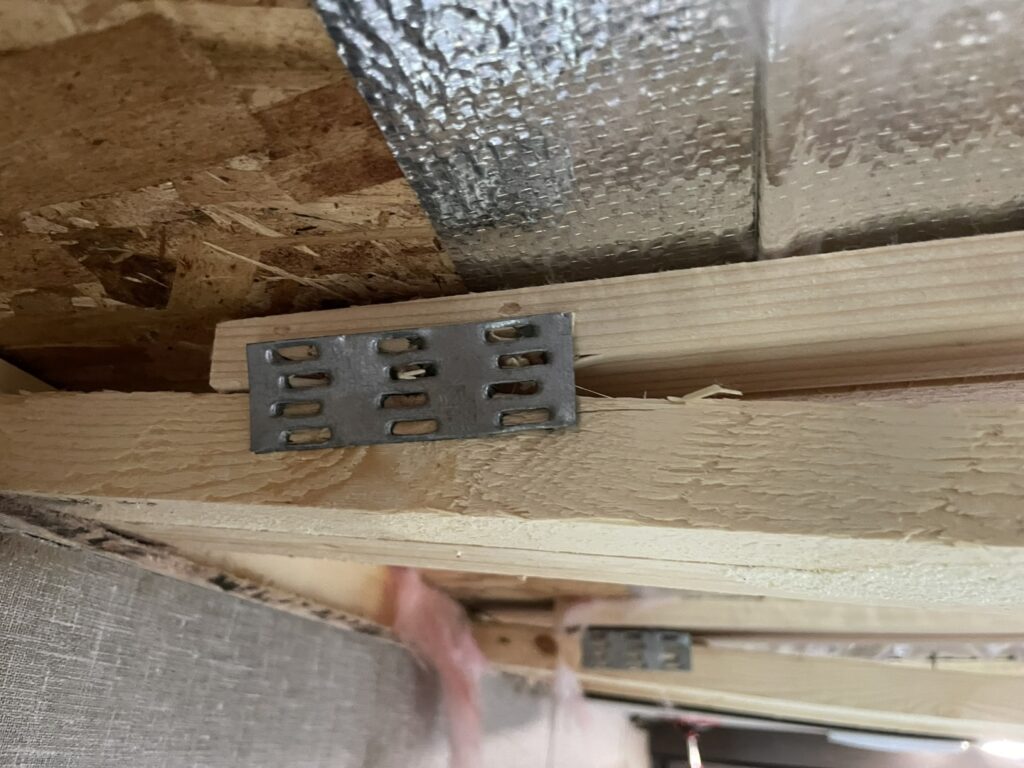

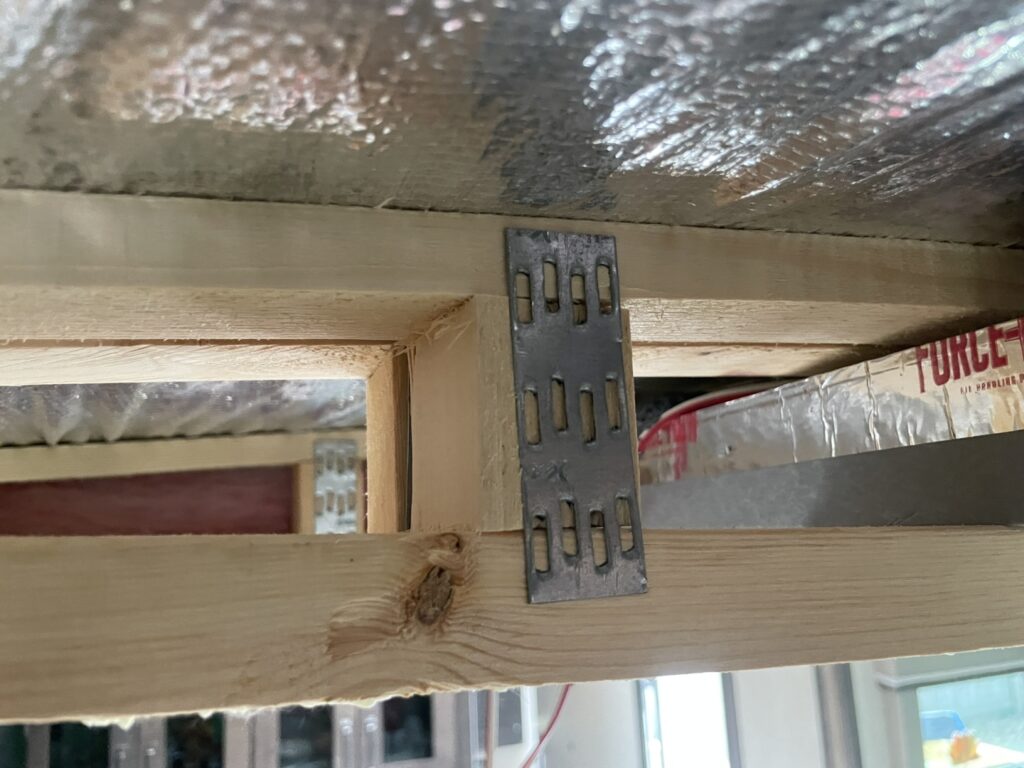

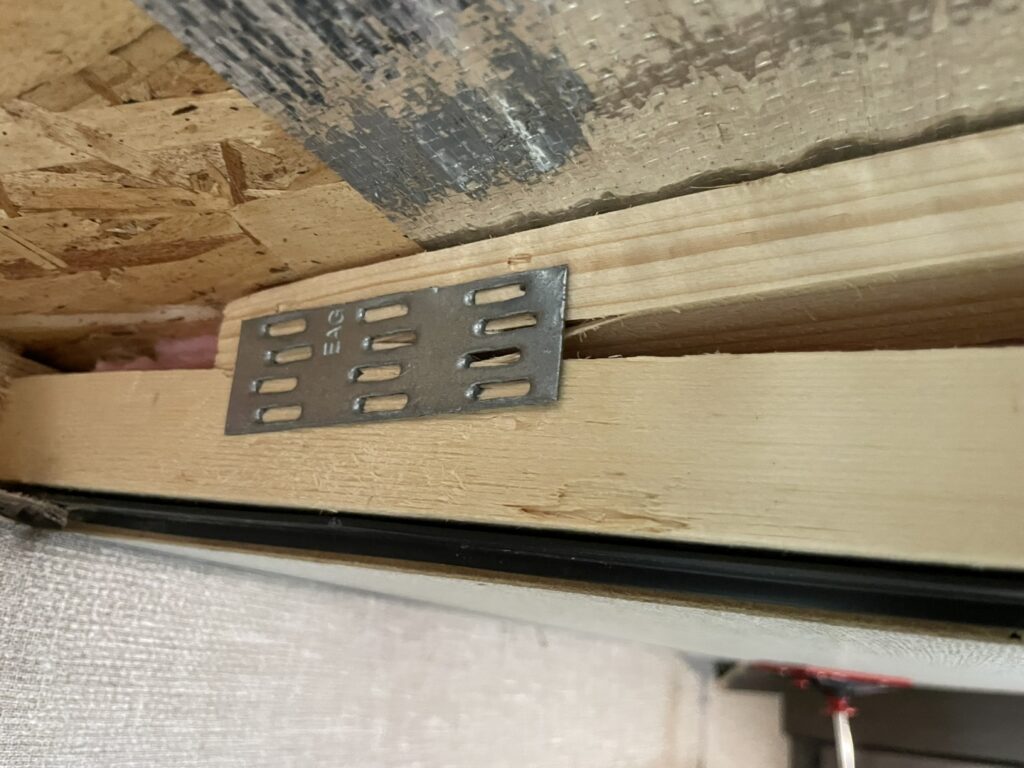

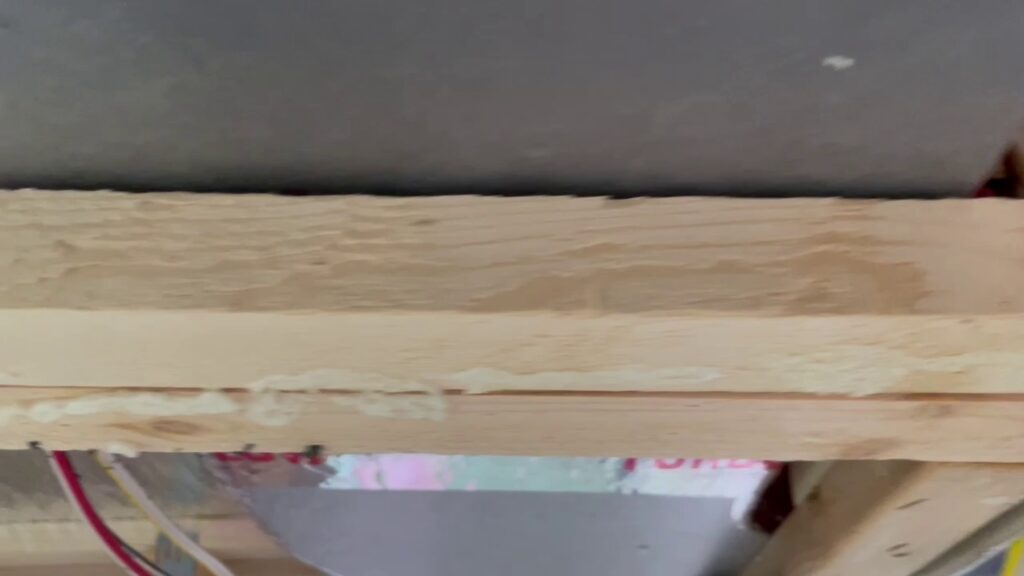

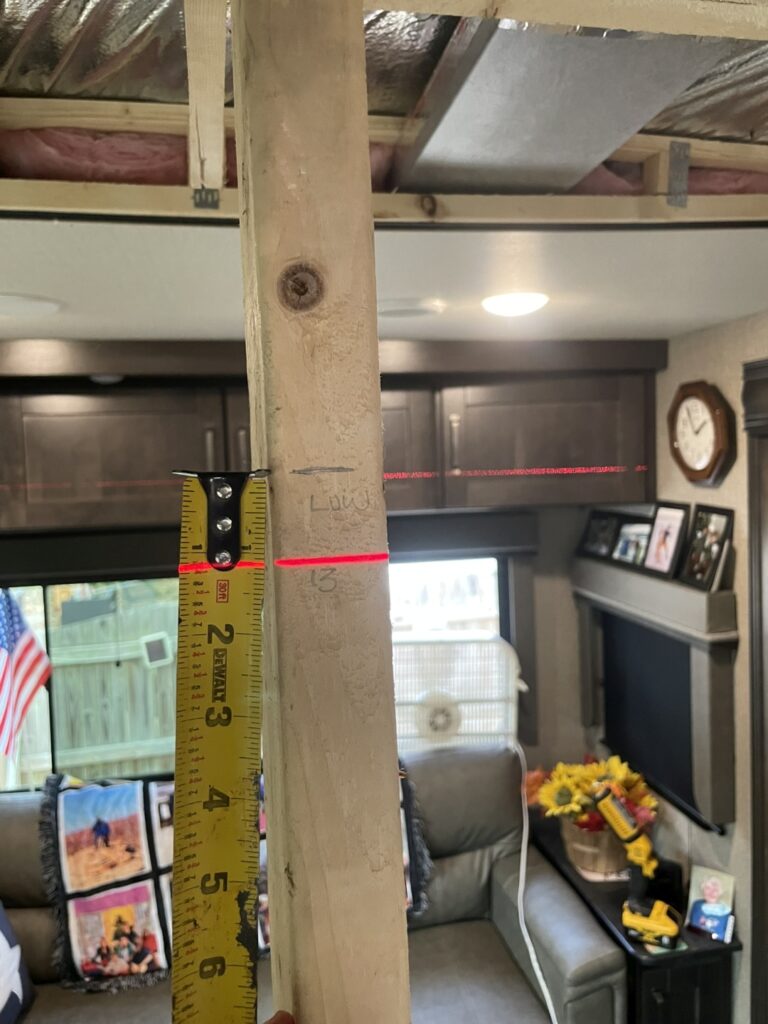

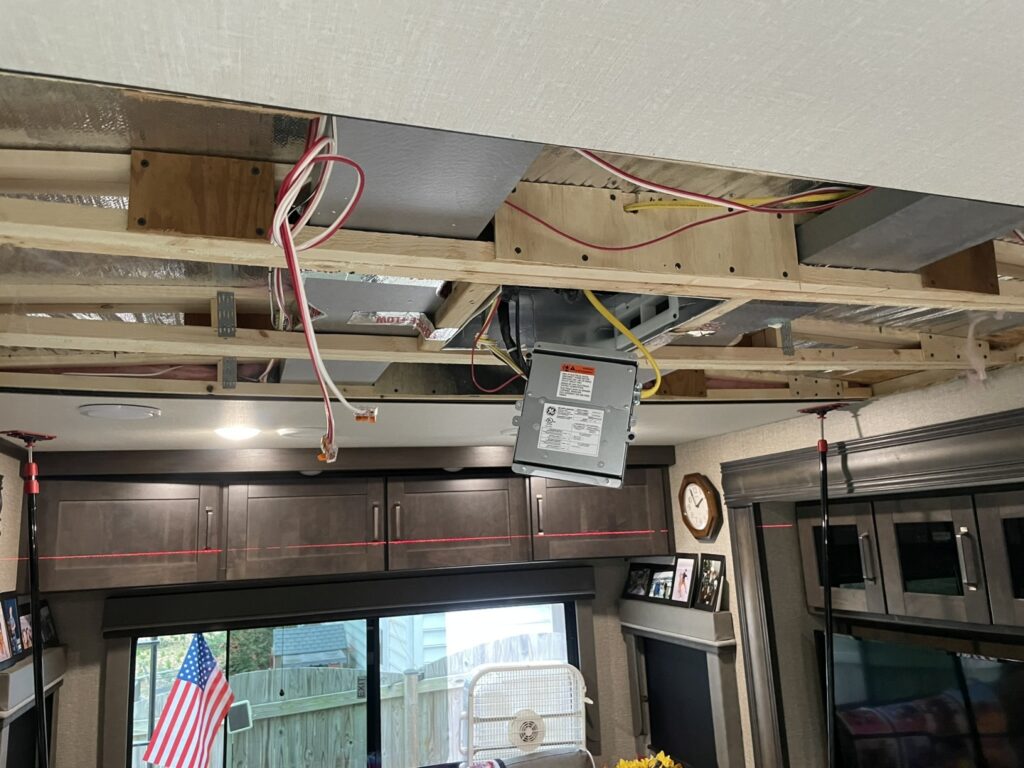

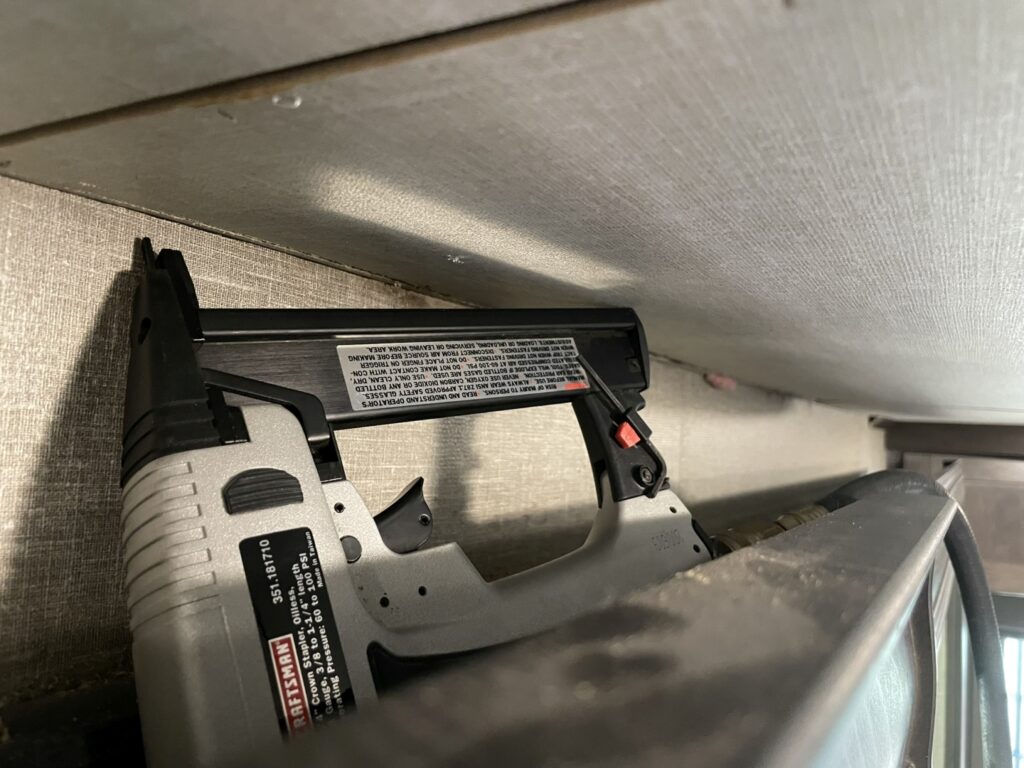

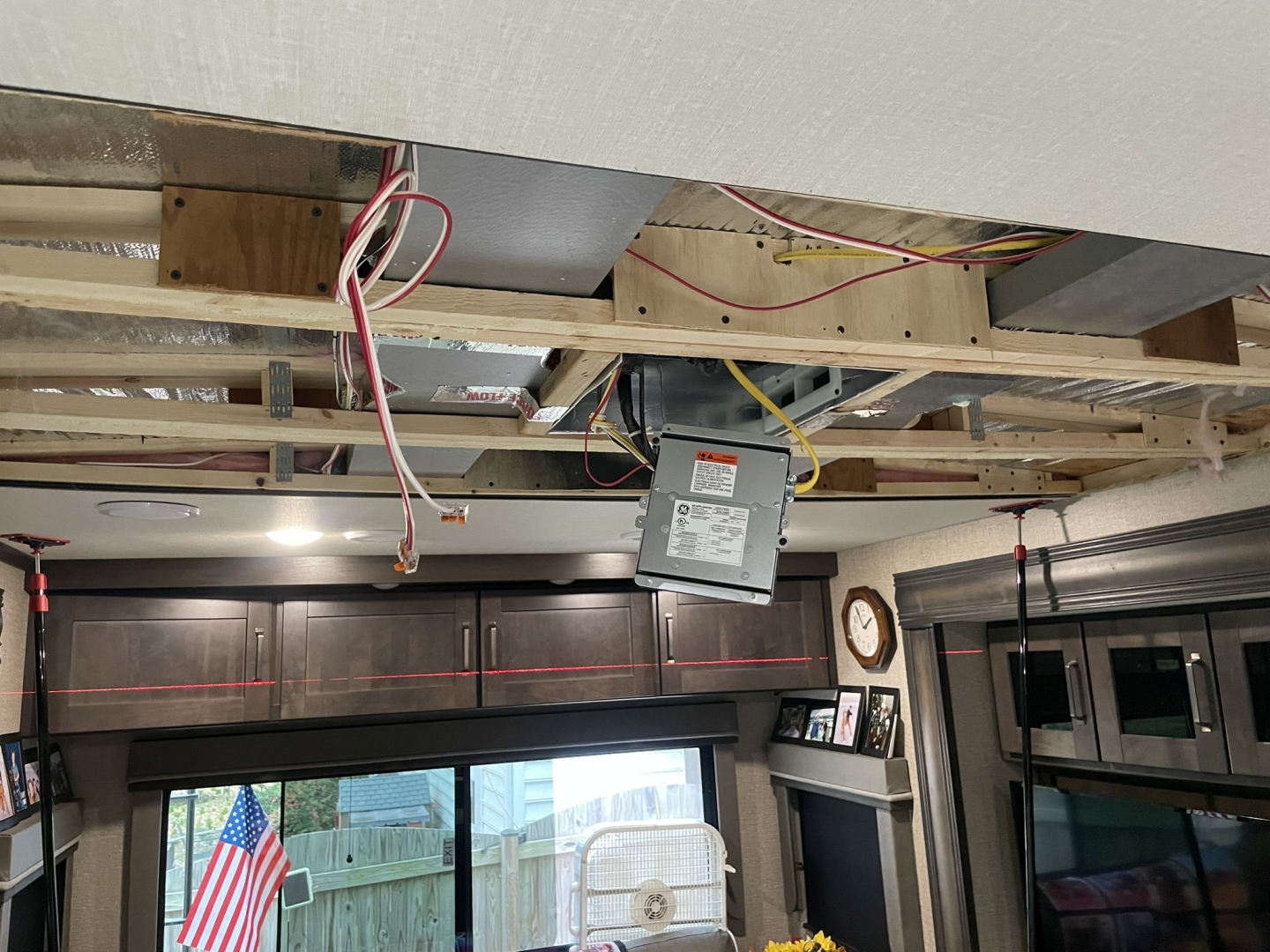

Shortly after the incident occurred and I had a chance to clear the damage, I reached out to our mobile mechanic who was convinced the only way he or any repair shop could fix it, would be to remove the entire roof and rebuild it. In traditional skeptical fashion, I felt there was a better way, so I started by pulling the ceiling panel down from the inside. This wasn’t terribly difficult but mainly awkward working alone in the confined space. It came down quickly after removing the T-molding, crown molding and borrowing Brian’s flush cut saw to cut the edges that were trapped by the wall boards. Next I pulled the insulation down so I could finally reveal the damage. As I had thought, the lightly constructed trusses had many of the joint compromised by the limb’s impact. I used a little redneck ingenuity to jack the ceiling back to the proper height (+a little extra assuming some sag would occur once the jack’s pressure was released). From there I fashioned gussets that would sister the trusses at those weak spots. I ended up adding 18-20 of those reinforcements at various locations to stiffen and hold the trusses into their correct profiles. To my relief, when the ceiling was relaxed again, it remained nice and flat once more just as it did from the factory.

From there I re-insulated, hung the ceiling panel and reused the trim such that no one will ever know I was in there.

When it was all done, I spent right about a day on the repair and likely saved north of $10,000 based on what I’ve heard an RV roof replacement would cost. And yes, that tree is on the shortlist for removal.